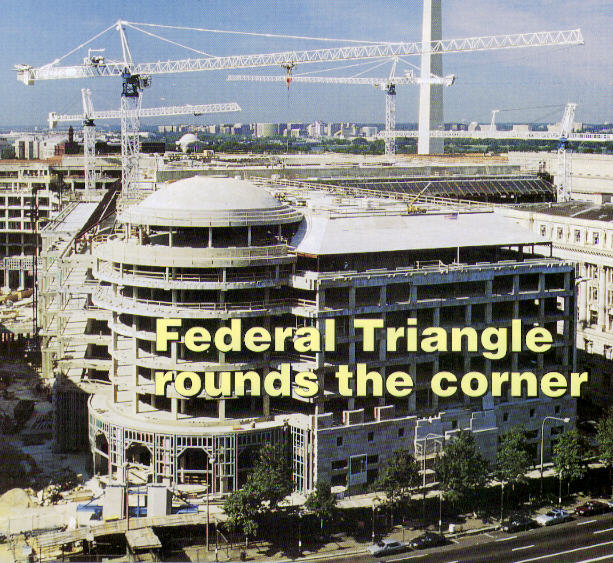

Slurry Rock Socket Overrun DSC

(on behalf of contractor)

The contractor was required to socket 2 ft into rock along

the perimeter slurry wall. In the early stages it was apparent that the

rock socketing would be overrun.

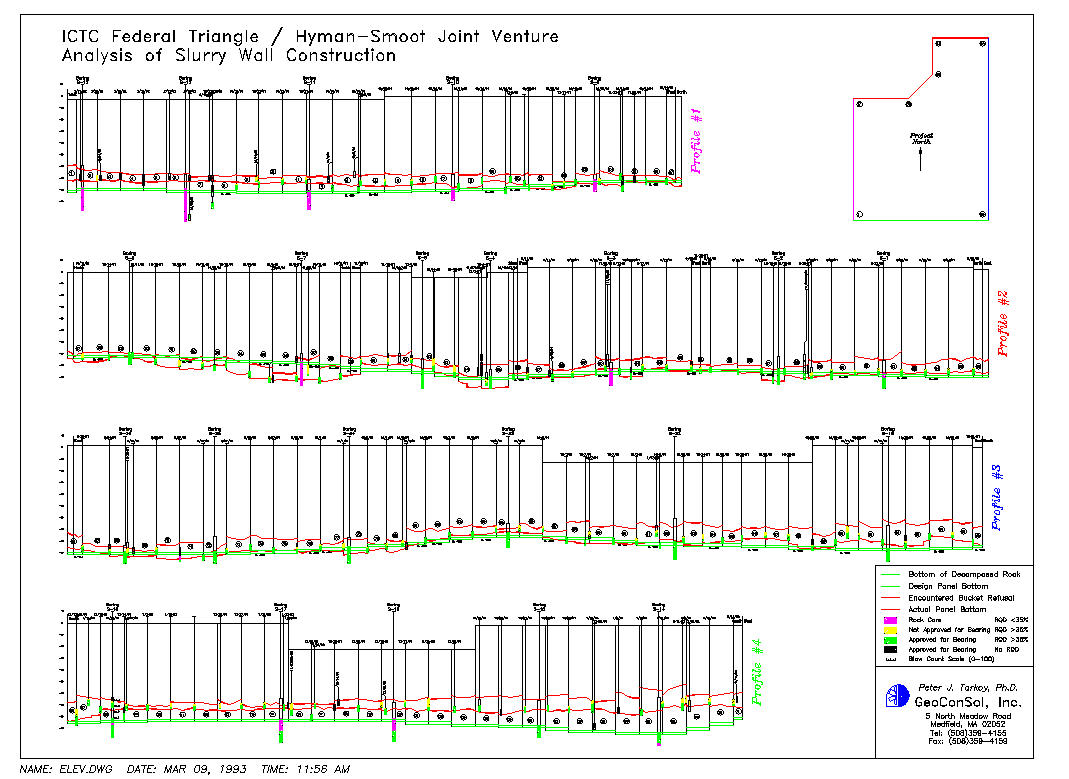

When the socketing was completed, we prepared a graphic

representation of the slurry walls and respective rock sockets to illustrate

anticipated and encountered conditions here below...

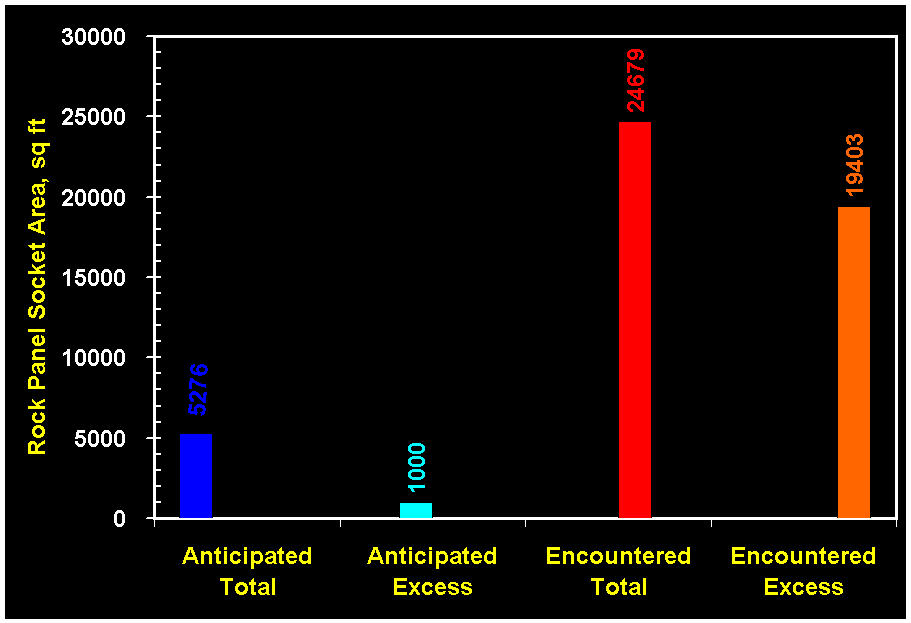

The data from the panels was summarized by illustrating the

anticipated, anticipated excess, encountered, and encountered excess rock

socketing area. The socketing area was overrun by a factor of 7.5.

The original borings were done using a hollow stem

auger. Refusal of the auger was taken as the top of un-decomposed

rock. The specifications required a 2 ft deep socket of the slurry wall

into rock.

In effect, the rock tools were unable to excavate decomposed

rock to the depth of the auger refusal.

The auger refusal was not a viable measure of the top of rock

for slurry wall socketing.

CONTRACTOR PREVAILED |