Pipe Failure

---

on behalf of pipe manufacturer ---

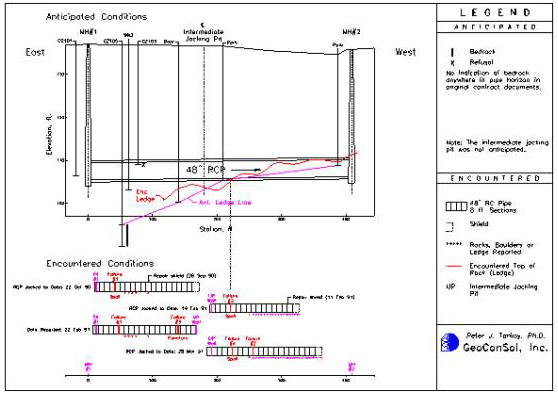

We were engaged to investigate the cause of jacked pipe failures on behalf of the pipe manufacturer.

Our investigation included test results of the pipe material, operational jacking

forces, shift records, and critical spatial relationships.

It was found that:

-

the

pipe did not fail at the location of the highest stress at the jacking pit

-

pipe

failures occurred on Mondays

-

other

pipes failed on Tuesdays when Monday was a holiday

-

failure

occurred on multiple occasions where the soil/rock interface crossed the

pipe envelope

-

the

concrete strength exceeded specifications and distributed jacking loads

The inevitable conclusion were:

-

the

jacked pipe was not lubricated properly

-

the

soil rock/interface was inadequately excavated & pipe traveled out of

alignment over the rock

-

the

pipe continued to be out of alignment setting the stage for future failures

-

point

loads / stress concentrations as a result of out of alignment pipe were responsible for the failures

CASE SETTLED AMICABLY

|